While the frequency of maintenance depends on usage and the operator’s standards – cotton candy vending machines are generally required to be serviced twice a week, requiring 30 minutes each time. There are multiple components when it comes to servicing a cotton candy vending machine, let’s break it down:

What Needs to Be Serviced

Cotton candy vending machines require the operator to restock 3 different materials and empty out the waste produced by the machine. The materials required to restock your machine and the frequency at which you have to do this is as follows:

1) Water Replacement: After producing 150 servings of cotton candy, the water used for humidity control in the machine must be refilled. This is a simple task but critical to ensure that the machine can continue running efficiently.

2) Sugar Refill: Depending on the machine, sugar needs to be refilled after every 300 servings.

3) Refilling Cotton Candy Sticks: An average cotton candy vending machine holds 300 sticks, so operators should expect to restock this when restocking sugar.

4) Emptying Wastewater Buckets: The waste water buckets should be emptied every 150 servings to prevent overflow. This bucket is responsible for collecting left-over sugar residue.

Cleaning the Machine

Beyond simple refilling, cotton candy vending machines need thorough cleaning to maintain hygiene and a presentable appearance. After all, no customer wants to purchase from a dirty machine. Operators should follow a consistent cleaning schedule:

1. Cleaning the Inside Cabinet: The interior of the machine, where the cotton candy is spun, should be cleaned every 100 servings. This helps prevent the buildup of sugar residue and keeps the machine looking professional. A clean interior also ensures that the cotton candy produced is free from contaminants.

2. Wiping Down Windows: The transparent windows that allow customers to watch their cotton candy being made are a huge part of the machine’s appeal. However, sugar can build up on these surfaces over time, creating a foggy, unattractive appearance. Cleaning the windows regularly ensures the machine remains visually appealing to customers.

Deep Cleaning Tasks

Deep cleaning task are not required to be performed every time an operator restocks or cleans his machine. These task should be done either weekly or bi-weekly to ensure smooth operation. They include:

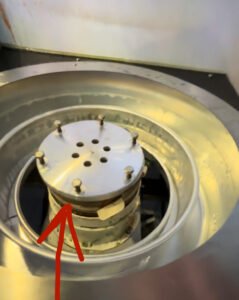

1. Cleaning the Burner Cover Plate: The most time-consuming part of cotton candy vending machine maintenance is cleaning the burner cover plate, which should be done weekly. This piece of equipment sits right on top of the furnace cover head (shown on the left), and is responsible for containing the melted cotton candy sugar. After a week of use, sugar residue can build up on the cover plate, reducing efficiency and leading to many issues. To clean the burner cover plate, the operator must disassemble it into three parts and use a three-part sink to remove the sugar residue completely.

2. Cleaning the Furnace Cover Head: While this task is only required once a month, it is crucial to the machine’s overall operation. The furnace cover head is the component that heats the sugar to its melting point. Over time, residue can accumulate here as well, and while the cleaning process only takes around 10 minutes, it is a vital step in maintaining the machine’s performance. A clean furnace cover head ensures the machine operates efficiently and continues to produce high-quality cotton candy. Check out our furnace head cleaning guide here

Frequency of Maintenance

While some of these tasks must be performed after specific quantities of servings, the overall frequency of maintenance will vary depending on how heavily the machine is used. In most locations, operators can expect to clean and restock their cotton candy vending machines once or twice a week. High-traffic areas, such as amusement parks or shopping malls, may require more frequent attention, while machines in quieter locations may need less.

The key to successful maintenance is consistency. Regular cleaning and upkeep prevent breakdowns, ensure customer satisfaction, and help prolong the life of the machine. If you are interested in having a cotton candy vending machine at your business but not interested in the maintenance and up-keep, reach out to our sales team to learn more about our turn-key solution.

Conclusion

Cotton candy vending machines offer a fantastic blend of entertainment and convenience, but they require regular maintenance to stay in top condition. From routine cleaning of the inside cabinet and windows to more intensive tasks like cleaning the burner cover plate, maintaining these machines requires attention to detail and commitment. By following the recommended maintenance schedule, operators can ensure that their cotton candy vending machines provide a reliable, enjoyable experience for customers and remain a profitable addition to any vending business.