We’ve been operating cotton candy vending machines since their inception and have learned a thing or two about best practices. We’re going to tell you all the mistakes we made so you don’t have to make them yourselves.

Extra Parts to Order For Your Cotton Candy Vending Machine

Like all machines, the cotton candy machine breaks down. And when they do, you want to make sure you have the parts on hand to fix it (otherwise, enjoy waiting 1-2 weeks to receive them from China!). Here are some basic recommendations:

1. The Furnace: This component heats and spins the sugar onto the cotton candy stick. Given its constant use, it typically needs to be replaced annually due to wear and tear. To extend the furnace’s lifespan, be sure to follow our maintenance guide here.

2. Water Pump: The water pump regulates the humidity inside the machine’s cabinet. Since it’s used with every production cycle, operators usually need to replace this part once a year.

3. Sugar Motors: These motors are responsible for dispensing the sugar and, due to frequent use, also tend to wear out over time. Plan on replacing them annually.

There’s a lot more to ordering extra parts, and if you want more info, check out our blogs on what breaks most often.

Cleaning Your Machine

Keeping cotton candy vending machines clean goes beyond just refilling them—it’s about maintaining hygiene and ensuring they look inviting. No one wants to buy from a machine that looks dirty (see below) Operators should stick to a regular cleaning routine to keep things running smoothly:

1. Cleaning the Inside Cabinet: The interior, where the cotton candy is spun, needs a good cleaning after every 100 servings. This prevents sugar buildup and keeps the machine looking professional. Plus, a clean inside ensures the cotton candy stays fresh and free from any unwanted particles.

2. Wiping Down the Windows: The clear windows are a big draw, letting customers watch the cotton candy being made. But over time, sugar can collect, leaving the windows foggy and unappealing. Regularly cleaning these windows helps maintain the machine’s visual charm and keeps customers coming back. For more info on best cleaning practices, check out some of other blog post.

Restocking Your Machine

The key to successfully operating a cotton candy vending machine is staying on-top of the frequent restocks they require. There are three main materials to replenish, plus sugar waste removal. Here’s a breakdown of what needs attention and how often:

1. Water Replacement: After about 150 servings, the water used for humidity control needs to be refilled. While a quick task, it’s essential for keeping the machine operating efficiently.

2. Sugar Refill: The sugar supply typically lasts for 300 servings, so operators will need to top it off regularly to keep production going.

3. Restocking Cotton Candy Sticks: Most machines hold around 300 sticks. Expect to restock these when refilling the sugar to ensure the machine stays stocked and ready for customers.

4. Emptying Wastewater Buckets: After every 150 servings, the wastewater bucket—responsible for collecting leftover sugar residue—should be emptied to prevent overflow and ensure the machine continues to function properly.

Yes…More Cleaning: Deep Cleaning

Deep cleaning tasks don’t need to be done every time the machine is restocked or cleaned. However, performing these tasks weekly or bi-weekly is essential to keep the machine running smoothly. These tasks include:

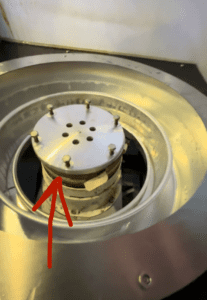

1. Cleaning the Burner Cover Plate: The most time-intensive maintenance task for a cotton candy vending machine is cleaning the burner cover plate, which should be done weekly. This plate sits above the furnace cover head and contains the melted sugar. After a week of use, sugar residue builds up, affecting the machine’s efficiency and potentially causing issues. To clean it properly, the operator must disassemble it into three parts and use a three-part sink to thoroughly remove the sugar buildup.

2. Cleaning the Furnace Cover Head: Though this task only needs to be done once a month, it’s critical for the machine’s overall function. The furnace cover head is responsible for heating the sugar to its melting point, and over time, residue can accumulate here as well. While the cleaning process takes just about 10 minutes, it plays a vital role in keeping the machine running smoothly and ensuring the cotton candy produced is top quality.